The Ultimate Guide: How to Achieve Perfect, Dust-Free Cuts on Laminate & LVP Flooring

The Messy Truth About Flooring Installation

Every flooring professional knows the scene all too well: a room filled with the deafening roar of a power saw, fine dust settling on every surface, and hours of cleanup after the installation is "done." It’s inefficient, unhealthy, and leaves a poor impression on the client.

Today, we end this. This guide will introduce you to a smarter, cleaner, and more professional way to cut flooring.

The Pain Points of Traditional Cutting Methods

For years, miter saws and jigsaws have been the standard. But they come with unavoidable problems:

1.The Dust:Cutting laminate and Luxury Vinyl Plank (LVP) creates a huge amount of harmful, fine dust that is a health hazard and a nightmare to clean.

2.The Noise:The loud noise from power tools is not only disruptive to the installer but also a major issue when working in occupied homes or apartments.

3.The Inconvenience:You need a power source and are often forced to cut outside or on a balcony, wasting precious time walking back and forth.

The Solution: The Professional Manual Flooring Cutter

Now, imagine this: you are in the client’s living room, right next to where you're laying the planks. You make a perfect, silent cut in seconds. There is zero dust. This isn't a dream; it's the revolution brought by professional manual flooring cutters.

Using the power of leverage and a hardened tungsten steel blade, a manual cutter slices through flooring like a guillotine, leaving a clean, factory-edge finish.

How to Make the Perfect Cut with AffluxCut: A 3-Step Guide

Using our cutters is incredibly simple:

1. Measure & Mark: As you normally would, use a pencil to mark the cut line on your plank.

2. Position & Secure: Place the plank on the AffluxCut platform, aligning the blade with your mark. The integrated fence and hold-down ensure the plank remains perfectly still.

3. Press & Cut: With a smooth, firm motion, push the handle down. With a satisfying "snick," your dust-free, precise cut is complete.

This method works flawlessly for standard 90-degree cross-cuts and is equally efficient for rip cuts (lengthwise cuts).

Why Professionals Choose AffluxCut

Our tools are engineered to solve the real-world problems you face on the job site. They don't just get the job done—they elevate your craftsmanship and professionalism.

Ready to say goodbye to dust and noise and hello to a more efficient way of working?

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

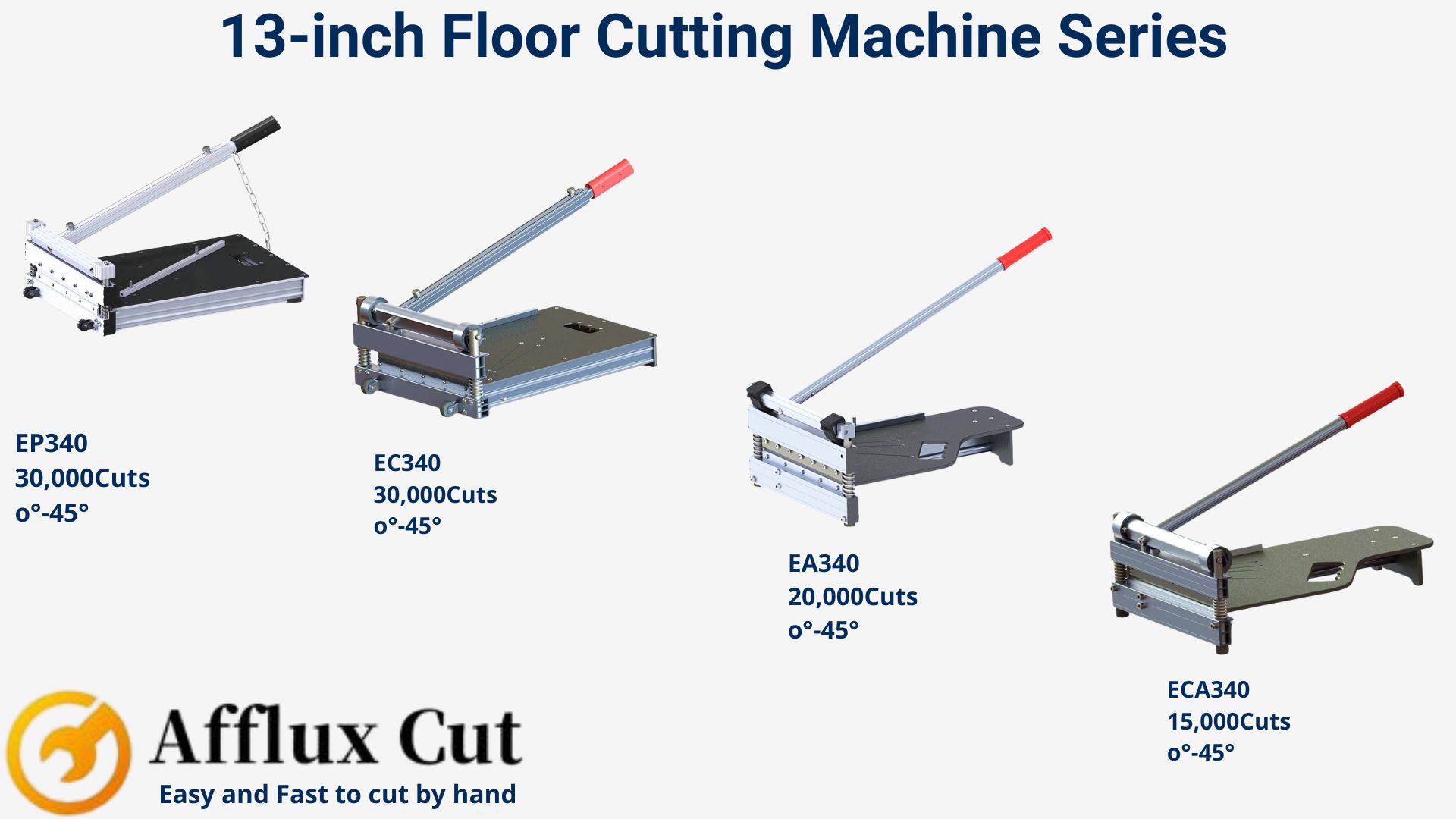

Inside the EC340: Why This Model Is Popular in the U.S. Market

Inside the EC340: Why This Model Is Popular in the U.S. Market