About Us

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

Views : 35

Update time : 2026-01-19 12:41:55

At AffluxCut, we continue to manufacture and ship manual flooring cutters for distributors, wholesalers, and tool brands worldwide. While we may not always be loud on social media, our factory floor remains active every day.

Each flooring cutter goes through:

-

Trial cutting before packing

-

Structural and blade inspection

-

Packaging checks before shipment

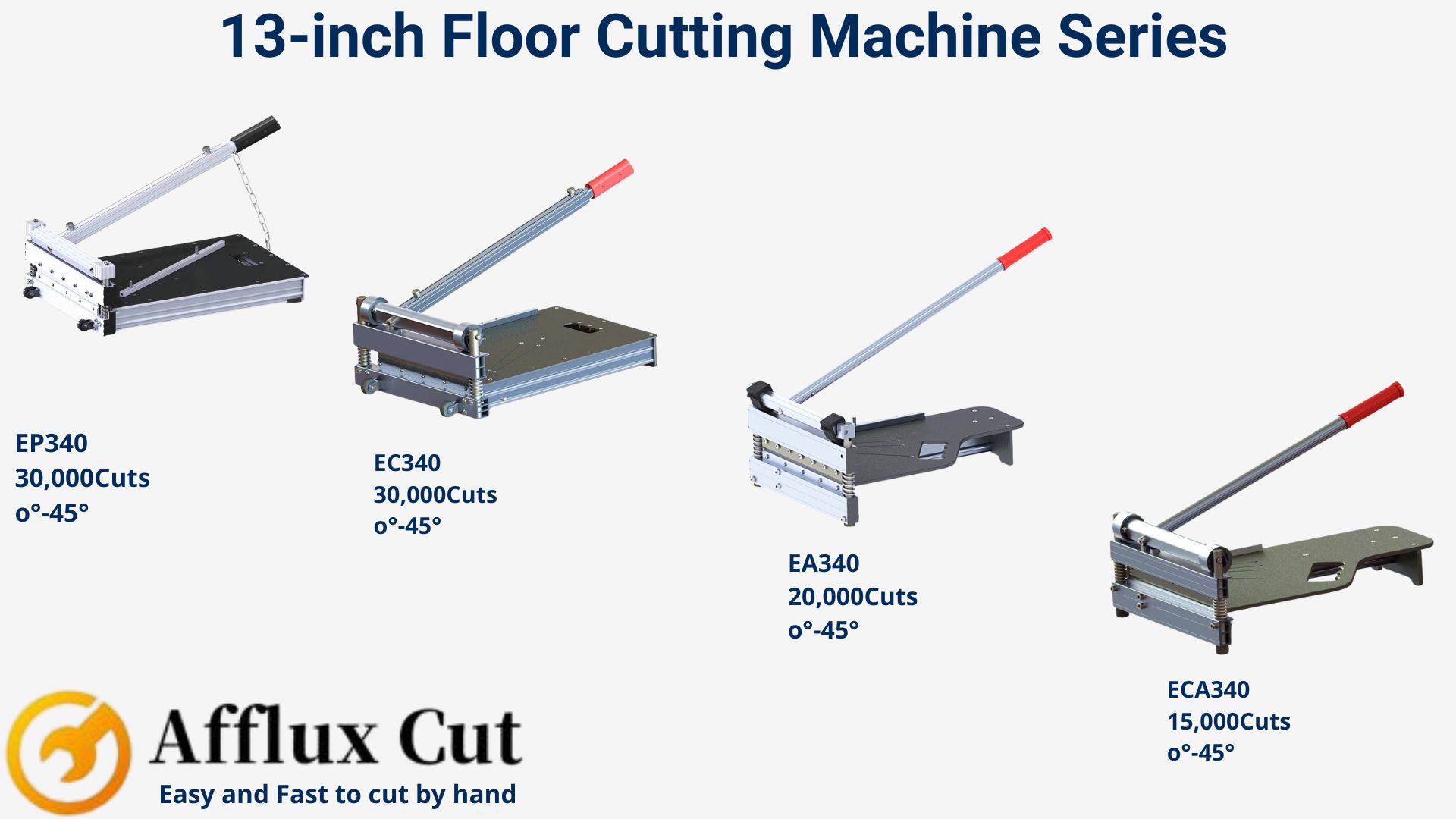

From EP series heavy-duty models to EC and ECA series with upgraded effort-saving design, our team ensures every unit meets consistent performance standards.

Whether it’s a trial order or a repeat shipment, we treat every order with the same level of attention and responsibility.

AffluxCut is still here — producing, improving, and supporting our partners globally.

相关新闻

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

Jan 19,2026

Over the past months, we’ve been fully focused on what matters most — production, quality control, and on-time delivery.

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Dec 17,2025

Why flooring distributors prefer OEM manual flooring cutters: better margins, product control, stable quality, and long-term supply reliability from the factory.

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Dec 09,2025

Dust-free. Quiet. Efficient. Manual flooring cutters are quickly becoming the go-to choice for LVP and SPC installations in 2025. As global markets shift toward safer job sites and higher installation efficiency, demand from distributors and OEM brands continues to grow. AffluxCut is developing next-generation models to deliver even stronger performance for the modern installer.

Inside the EC340: Why This Model Is Popular in the U.S. Market

Inside the EC340: Why This Model Is Popular in the U.S. Market

Nov 25,2025

Among all manual flooring cutters available today, the AffluxCut EC340 has become one of the most widely accepted models in the U.S. market — especially among flooring distributors, tool retailers, and contractors looking for a more ergonomic, dust-free solution.

Behind its popularity is not only cutting performance, but a thoughtful design approach built around comfort, durability, and real job-site efficiency.

This article breaks down what makes the EC340 a standout cutter and why U.S. professionals consistently choose this model over traditional saws and other manual cutters.