Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

For flooring professionals, 2025 is shaping up to be a year of rapid change. More installers are shifting toward LVP, SPC, and laminate floors, while global regulations continue tightening around job-site safety and dust control. In this environment, one category is emerging as a surprisingly powerful solution:

![[浮云]](http://img.t.sinajs.cn/t35/style/images/common/face/ext/normal/bc/fuyun_thumb.gif) Manual flooring cutters — dust-free, durable, and highly cost-efficient.

Manual flooring cutters — dust-free, durable, and highly cost-efficient.

At AffluxCut, we have seen a significant rise in distributor inquiries over the past few months. And the trend is clear: the global market is ready for better, simpler, and cleaner cutting tools.

Here’s why manual flooring cutters will play an even bigger role in 2025.

1. Dust-Free Cutting Meets Global Regulations

Across the U.S., Europe, and Australia, more job-site standards are pushing installers to reduce airborne dust.

Power saws create fine particles that require vacuum extractors and PPE — adding cost and slowing down small jobs.

Manual cutters eliminate dust entirely.

No electricity, no noise, no cleanup.

This makes them ideal for:

-

Residential installations

-

Renovation work in occupied homes

-

Commercial spaces with strict dust rules

-

Retailers and rental centers seeking “clean tools”

Dust-free work is no longer a bonus — it’s becoming a requirement.

2. The Rise of SPC & Click Flooring Drives Demand

SPC, rigid vinyl, bamboo laminate, and engineered composite flooring all require clean, chip-free edge cuts.

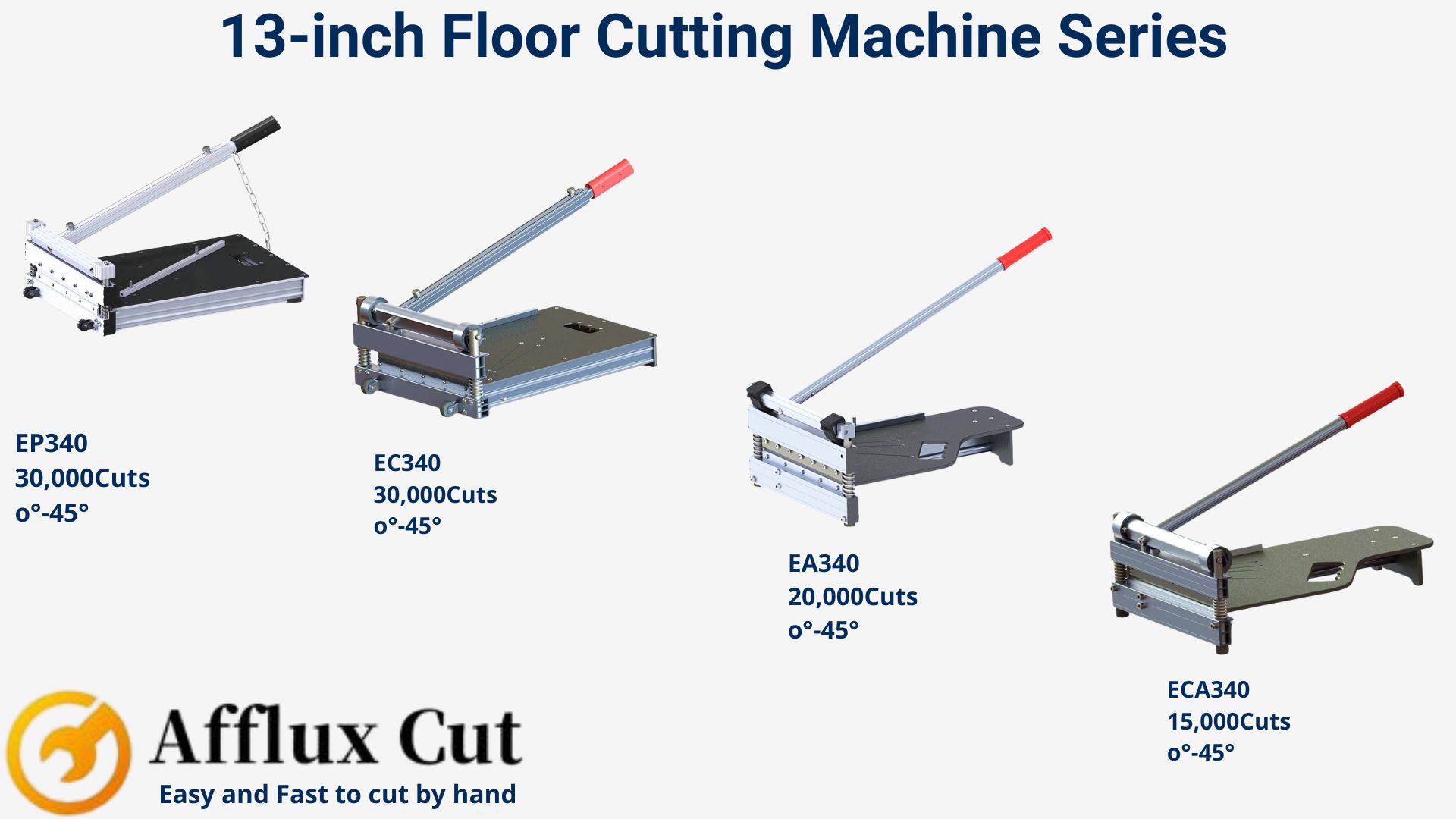

Modern cutters (like our EC340 / EA340 series) now offer:

-

Stronger blades and more stable bases

-

Wider cutting widths for long planks

-

Higher cutting angles for stair treads and transitions

As installers deal with harder, denser materials, a high-durability manual cutter becomes a valuable job-site partner rather than a backup tool.

3. Lower Total Cost of Ownership for Installers

A quality manual cutter lasts years, not months.

Installers and distributors appreciate:

-

No maintenance cost

-

No blade-burning or motor wear

-

Long service life

-

Cheaper logistics compared to power tools

For many flooring contractors, a $60–$150 manual cutter can replace hundreds of dollars in annual saw-related expenses.

In tough economic cycles, durability wins.

4. Faster Setup = Faster Jobs

Many installers now take on high-volume small jobs — bedrooms, offices, rental units.

They want tools that allow them to:

-

Start immediately

-

Cut quietly at night or in apartments

-

Work without power outlets

-

Reduce cleanup time

A manual cutter fits perfectly here.

No cables. No noise. No dust. No fuss.

5. OEM Demand Growing Among Distributors & Retailers

In 2024–2025, we’ve seen a growing shift:

Large distributors, Amazon sellers, and retail chains want private-label flooring cutters.

The reasons are simple:

-

Higher margins

-

Stronger brand positioning

-

Custom packaging for retail shelves

-

Stable and predictable manufacturing supply

-

Lower MOQ options for new channel testing

AffluxCut continues to support partners with:

OEM branding, customized packaging, color options, and Good-Better-Best product lines.

6. What’s Coming Next in Our Product Line?

We are currently developing new-generation manual cutters with:

-

Better cutting leverage for long-edge SPC cuts

-

Stronger reinforced frames

-

Higher angle capability

-

Improved blade durability

-

Lighter weight for overseas shipping

These upgrades are designed based on real installer feedback from the U.S., Germany, and Australia.

Our goal is simple:

Give professionals a cleaner, faster, more reliable cutting experience — at a better price point.

Conclusion: 2025 Belongs to Clean, Efficient, Manual Cutting

For global flooring distributors, the key question is no longer whether customers need dust-free cutters — it’s which model offers the best durability and cutting performance.

If your product lineup doesn’t yet include a high-quality manual flooring cutter, now is the right time to explore OEM opportunities.

AffluxCut supports:

-

Distributors

-

Retailers

-

Amazon & e-commerce sellers

-

Tool rental centers

-

Flooring installation companies

If you’re interested in adding a reliable, dust-free cutting solution to your portfolio, our team is ready to assist.

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Inside the EC340: Why This Model Is Popular in the U.S. Market

Inside the EC340: Why This Model Is Popular in the U.S. Market