From Order to Shipment – The Story Behind Our Flooring Cutter Production

Every successful product has a story, and at AffluxCut, our story begins with our customers.

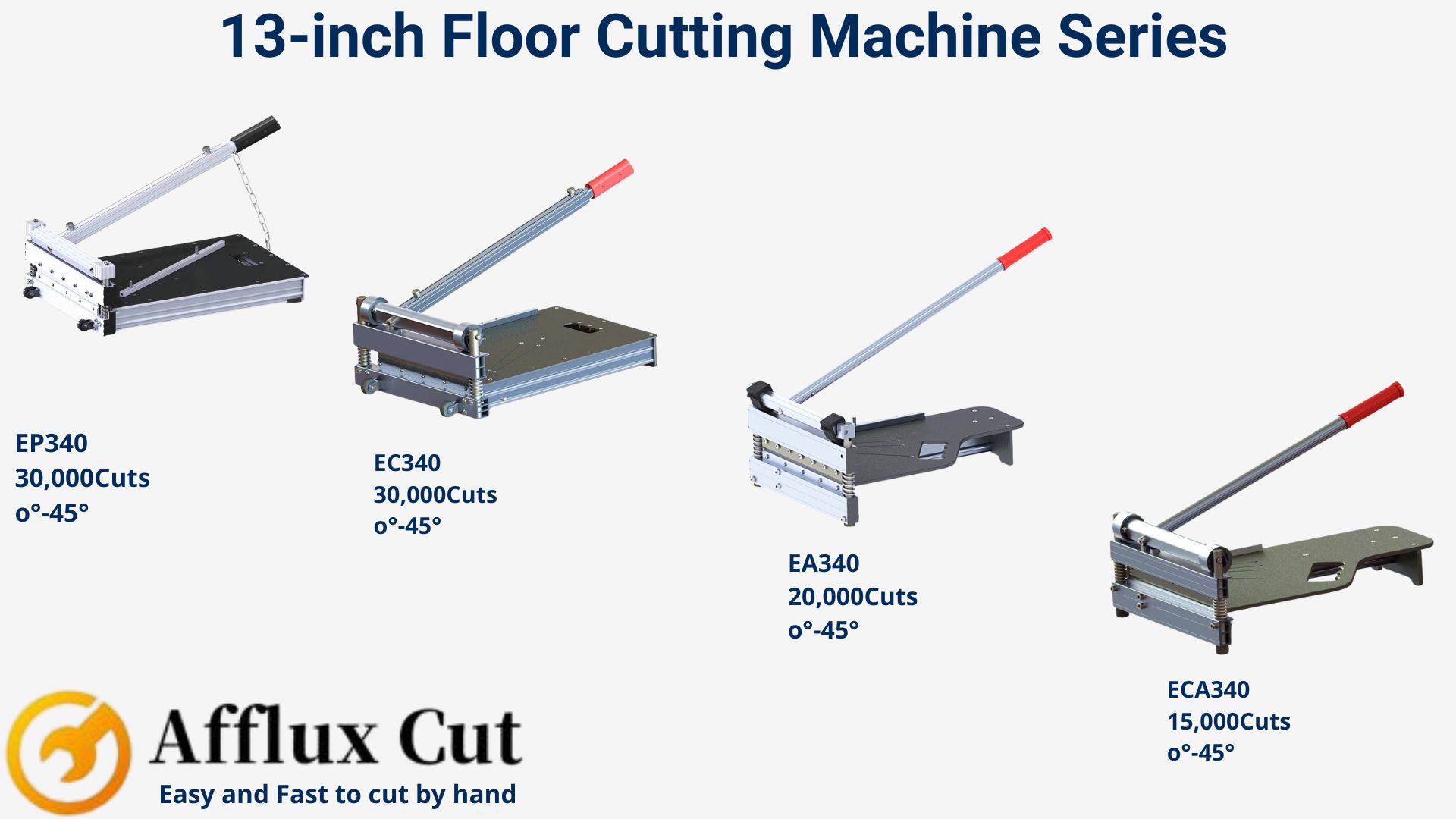

Recently, a U.S. distributor placed a large order for our manual flooring cutters — models designed for laminate, SPC, and vinyl flooring. Their requirement was clear: dust-free cutting, durable materials, and reliable supply to meet growing market demand.

Within days, our production line came alive. Rows upon rows of floor cutters were assembled, checked, and lined up, as shown in the images above. Each unit features:

-

Tungsten carbide blades for long-lasting sharpness

-

Heavy-duty steel construction for durability

-

Precise guides for professional flooring installation

This batch represents not only the strength of our factory but also the trust of our global partners.

When the order was complete, hundreds of carefully packed cutters left our facility, bound for retail shelves and professional contractors overseas. For the distributor, this shipment meant one thing: a competitive advantage in their local flooring tools market.

Why Global Buyers Trust AffluxCut

-

Reliable Supply Capacity – Capable of handling both trial orders and large-volume contracts

-

Dust-Free, Portable, and Noise-Free Design – Perfect for contractors and indoor projects

-

Flexibility – Standard models (EC340, EP340, ECA340) or custom branding options for OEM clients

At AffluxCut, every production run tells the same story: quality, reliability, and partnership.

If you are a flooring distributor, tool wholesaler, or retail supplier, our factory is ready to support your business with bulk production, competitive pricing, and custom solutions.

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Inside the EC340: Why This Model Is Popular in the U.S. Market

Inside the EC340: Why This Model Is Popular in the U.S. Market