Say Goodbye to Dust: The Rise of Manual SPC Flooring Cutters

An SPC floor cutter is a

hand-operated tool designed specifically to cut rigid SPC planks quickly and

accurately. Unlike electric saws, it doesn't require power or generate harmful

dust.

Manual SPC cutters allow

users to:

- Cut planks at precise

angles

- Trim end pieces with

clean edges

- Work indoors without

creating a mess

- Avoid the use of power

cords, batteries, or ventilation setups

In short: it’s the

installer’s best friend.

Manual Cutter vs Electric Saw: A Quick Comparison

|

Feature |

Manual Cutter |

Electric Saw |

|

Dust-Free Cutting |

✓ |

✗ |

|

Power Required |

✗ |

✓ |

|

Portability |

✓ |

✗ |

|

Safe for Indoor Use |

✓ |

✗ |

|

Noise Level |

Low |

High |

|

Setup Time |

Fast |

Slow |

|

Maintenance |

Low |

High |

For on-site, indoor

jobs—especially where cleanliness matters—manual cutters are becoming the

preferred tool for professionals.

Why Dust-Free Cutting Is a Big Deal

SPC is a dense, tough

material. When cut with electric tools, it often produces:

- Fine dust particles that

linger in the air

- Messy workspaces

requiring extra cleanup

- Health concerns for

installers breathing it in

- Possible violations of

indoor air quality standards

By switching to a manual

floor cutter, you eliminate all of these issues. The blade slices through

the plank with precision, without grinding or friction—leaving no airborne

particles behind.

What to Look for in a Manual SPC Cutter

Not all manual cutters are

built the same. For SPC in particular, you need:

- A hardened steel blade

for clean cuts

- A wide cutting platform

(preferably 300mm or more)

- Stable support feet to

prevent wobbling

- Angle guide for

precision miter cuts

- Comfortable handle with

good leverage

Pro tip: choose a model

tested to cut at least 12mm thick SPC material consistently. That’s the

benchmark for modern rigid core floors.

AffluxCut: Built for the Job, Trusted by Pros

At Afflux, we’ve

engineered our manual SPC cutters with the installer in mind.

✔ Reinforced steel frame – for

durability on job sites

✔

Blade designed specifically for SPC, WPC, and LVT materials

✔

Compact size, heavy-duty build –

ideal for both pros and DIYers

✔

Zero electricity, zero dust, zero compromises

Whether you’re fitting out an entire crew or just upgrading your tool collection, Afflux manual cutters will save time, reduce cleanup, and improve cutting results.

What Professionals Are Saying

“We used to bring a miter saw

to every job. Now we just bring the Afflux cutter. Quieter, cleaner, and just

as accurate.”

– Ray M., Installer, Florida

“I cut over 80 SPC planks in

one day without re-sharpening the blade. Total game-changer.”

– Luis T., Contractor, California

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

We’re Still Here: Behind the Scenes at AffluxCut Flooring Cutter Factory

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

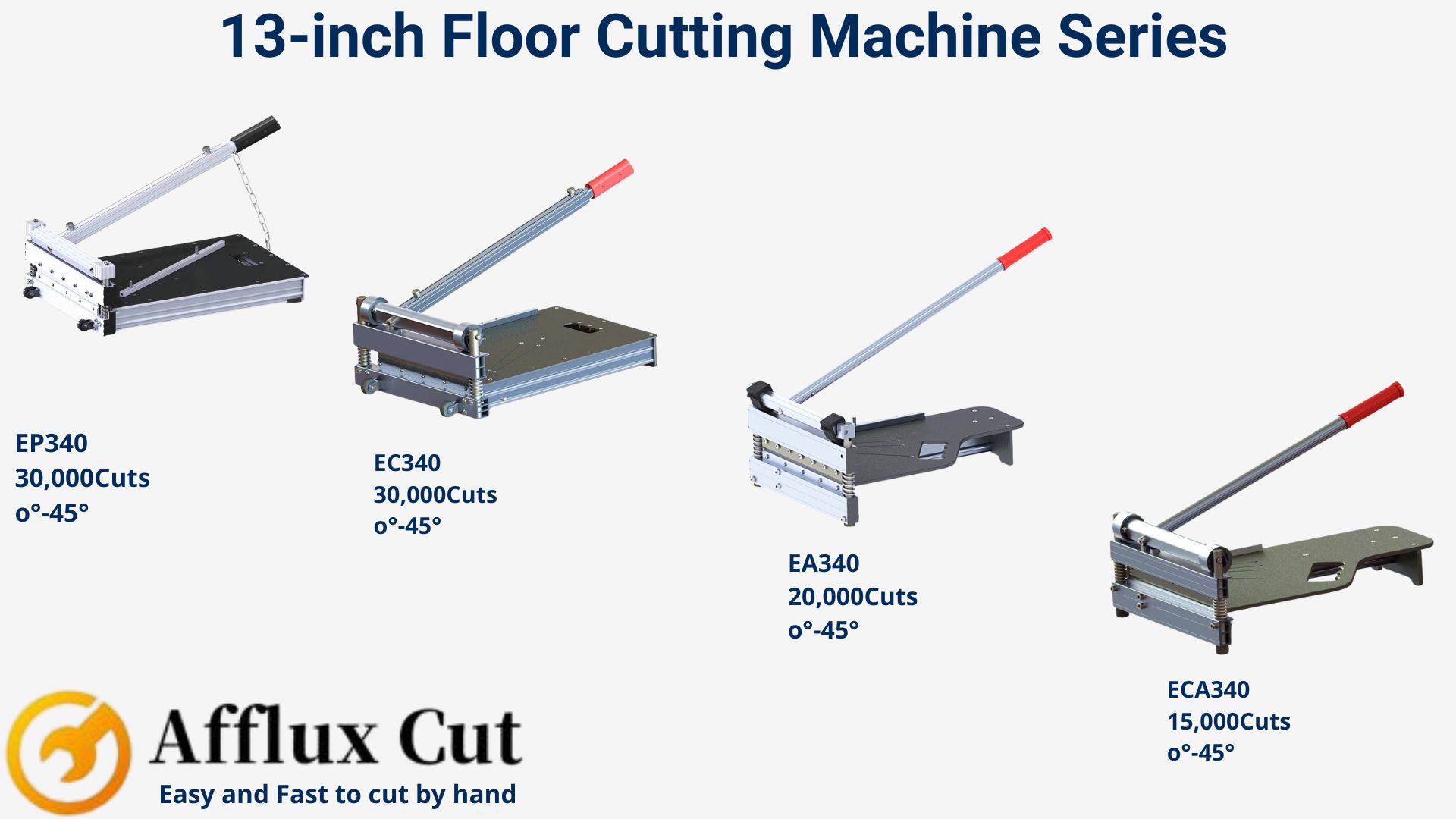

Inside the EC340: Why This Model Is Popular in the U.S. Market

Inside the EC340: Why This Model Is Popular in the U.S. Market