Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

More Distributors Are Choosing OEM — Here’s Why

In today’s competitive flooring market, distributors are under pressure.

Margins are tighter.

Products look similar.

And relying on “off-the-shelf” tools makes it harder to stand out.

That’s why more flooring distributors are choosing OEM manual flooring cutters — not just to sell a product, but to gain control over their business.

1. OEM Gives You Margin Control

When you sell generic, branded tools, your price is limited by the market.

With OEM flooring cutters, distributors can:

-

Set their own pricing strategy

-

Avoid direct price comparison

-

Build healthier, more stable margins

You’re not competing on price alone — you’re selling your product.

2. Product Differentiation Actually Matters

From the customer’s point of view, many cutters look “similar”.

OEM allows you to customize:

-

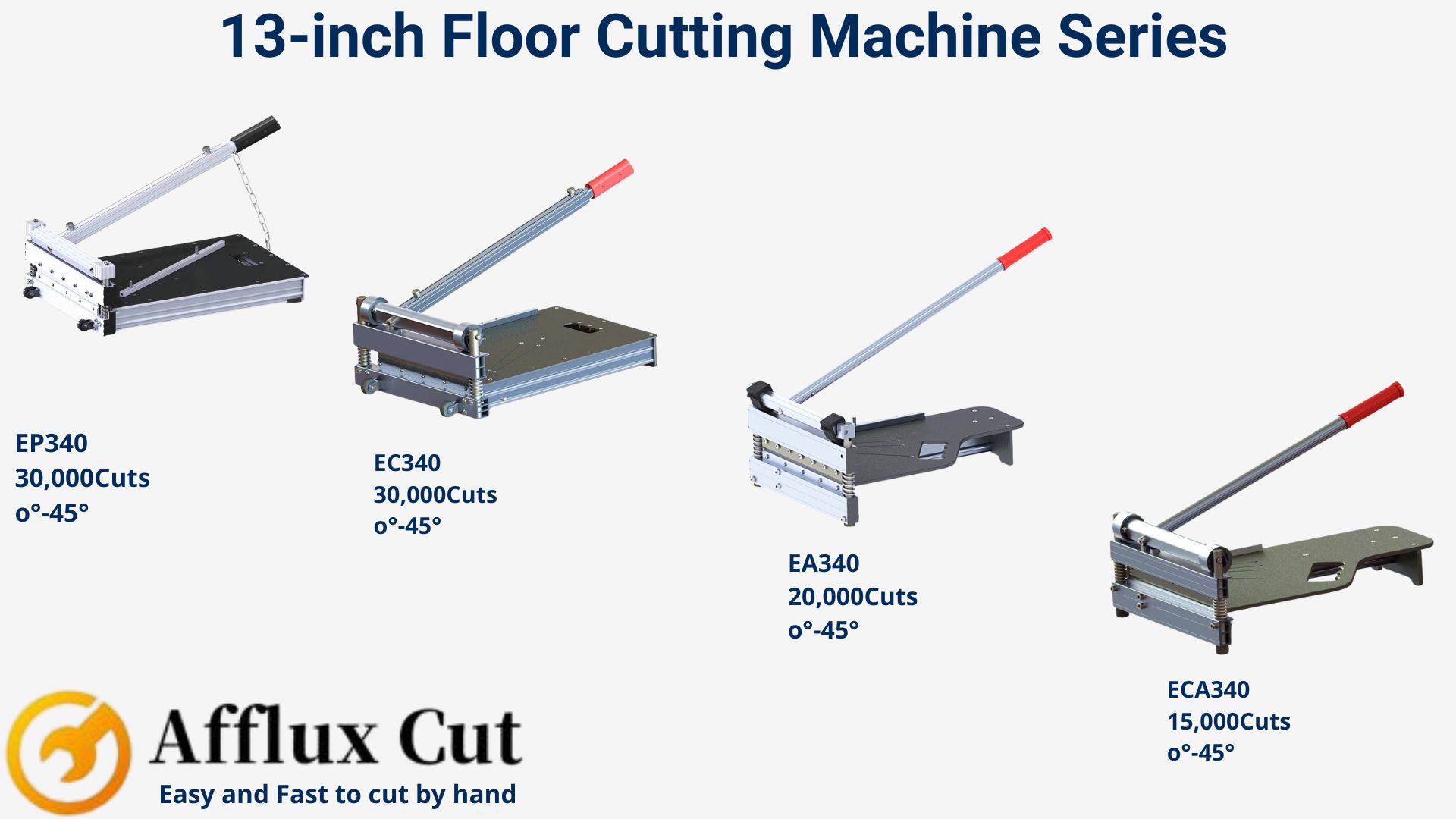

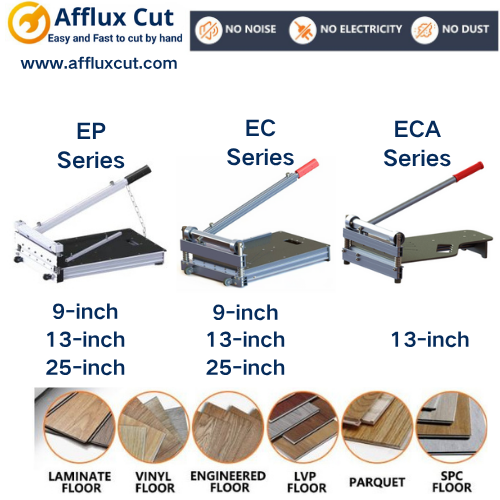

Model selection (EP / EC / ECA series)

-

Cutting capacity and structure

-

Color, logo, packaging

-

Accessories and manuals

Even small changes can clearly separate your product from competitors on the shelf.

3. Stable Quality Comes From the Factory, Not the Brand Name

Distributors don’t need more SKUs — they need fewer problems.

A direct factory relationship means:

-

Consistent production standards

-

Pre-shipment inspection

-

Faster feedback and improvement cycles

At AffluxCut, every flooring cutter is tested before shipment — because returns cost distributors far more than manufacturers.

4. OEM Supports Long-Term Supply, Not One-Time Orders

For growing distributors, continuity matters more than short-term deals.

OEM partnerships allow:

-

Stable reorders

-

Production planning

-

Better lead times during peak seasons

Small trial orders are welcome. Growth is planned together.

5. A Cleaner, Smarter Tool Fits Today’s Market

Manual flooring cutters are increasingly preferred because they are:

-

Dust-free

-

Noise-free

-

Electricity-free

These features align perfectly with:

-

Indoor installation requirements

-

Retail store demos

-

Environment-conscious markets

OEM distributors benefit from a product that already solves real-world problems.

OEM Is Not About Size — It’s About Direction

Whether you are:

-

A regional distributor

-

A flooring wholesaler

-

A tool brand expanding its lineup

OEM flooring cutters give you flexibility, control, and long-term value.

If you’re looking for a manufacturing partner who understands both production and international trade, AffluxCut is ready to support your next step.

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why Distributors Choose OEM Flooring Cutters — Not Just Products, But Control

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Why 2025 Will Be the Year of Manual Flooring Cutters: Dust-Free, Durable, and Cost-Efficient Solutions for Global Installers

Inside the EC340: Why This Model Is Popular in the U.S. Market

Inside the EC340: Why This Model Is Popular in the U.S. Market

How Retailers and Wholesalers Can Turn Flooring Cutters Into Profit Drivers

How Retailers and Wholesalers Can Turn Flooring Cutters Into Profit Drivers